Box Build Assembly Processing Companies in Singapore: Precision Solutions by Actenn

In today’s fast-paced industrial and technological sectors, streamlined box build assembly processing plays a critical role in ensuring seamless operations and optimized system integration. As one of the leading box build assembly processing companies in Singapore, Actenn provides turnkey solutions that bring together electrical, mechanical, and electronic components into fully integrated systems.

With a focus on precision, scalability, and quality, Actenn delivers tailored box build assemblies that meet the demands of industries such as automation, energy, medical, telecommunications, and aerospace. This section explores our expertise, key features, step-by-step processes, applications, and why businesses rely on Actenn as their preferred partner for box build solutions.

Introduction to Box Build Assembly Processing

Box build assembly processing refers to the design, assembly, and integration of multiple components into a single, ready-to-use enclosure. These components can include printed circuit boards (PCBs), wiring harnesses, connectors, sensors, mechanical brackets, and power supplies. This turnkey solution simplifies system installation, reduces time-to-market, and ensures reliable performance across various applications.

Actenn, a trusted box build assembly processing company in Singapore, specializes in delivering custom-designed systems that align with client specifications. From simple enclosures to complex integrated solutions, our expertise ensures precision engineering, enhanced functionality, and long-term durability.

Why Box Build Assembly Processing Is Critical

Box build assembly processing provides significant advantages for businesses, particularly in managing complex systems. Here are some key reasons why it is essential:

- Centralized Integration: Combines multiple components into a single enclosure for organized, optimized performance.

- Reduced Complexity: Simplifies installation and reduces on-site assembly time.

- Scalability: Modular designs allow for future upgrades and system expansions.

- Time Efficiency: Turnkey solutions minimize downtime and ensure faster deployment.

- Reliability: Precision-engineered assemblies improve system performance and reduce failures.

- Customization: Tailored solutions meet specific industry requirements and environmental conditions.

At Actenn, we address these critical needs by delivering high-quality box build assemblies that support businesses in achieving operational excellence.

Key Features of Actenn’s Box Build Assembly Solutions

As one of the leading box build assembly processing companies in Singapore, Actenn’s solutions are designed to meet the evolving demands of modern industries. Here are the key features of our services:

- Custom-Designed Solutions: Tailored box build assemblies to meet specific application requirements.

- High-Quality Components: Integration of premium-grade materials, including wiring, PCBs, connectors, and enclosures.

- Space-Optimized Layouts: Compact designs that improve airflow, reduce clutter, and simplify maintenance.

- Thermal and Environmental Resistance: Built to perform in temperature-sensitive and demanding conditions.

- Precision Wiring and Integration: Organized and labeled wiring for ease of installation and troubleshooting.

- Global Standards Compliance: Meets ISO 9001, IPC, and RoHS standards for quality, safety, and environmental responsibility.

- Comprehensive Testing: Electrical, mechanical, and functional testing to ensure optimal performance.

Actenn’s Core Offerings in Box Build Assembly Processing

Actenn offers a wide range of box build assembly services tailored to diverse industry needs. Below are our core offerings:

1. Power Distribution Box Assemblies

- Designed to manage and distribute power efficiently across systems.

- Features include breakers, fuses, transformers, and power monitoring tools.

- Suitable for industrial plants, energy systems, and commercial buildings.

2. Control Panel Assemblies

- Integration of programmable logic controllers (PLCs), human-machine interfaces (HMIs), and sensors.

- Optimized for real-time monitoring and automation control in industrial settings.

- Ensures safety and efficiency in manufacturing environments.

3. Custom Mechanical Enclosures

- Durable enclosures built to protect electrical and electronic components.

- Options include weatherproof, dustproof, and corrosion-resistant designs.

- Perfect for outdoor, energy, and telecommunications applications.

4. Cable and Wire Harness Integration

- Precision wiring for power, signal, and data transmission within assemblies.

- Reduces installation complexity and ensures organized cable management.

- Supports modular and high-density system requirements.

5. Turnkey Box Build Solutions

- Complete design, assembly, testing, and packaging of integrated systems.

- Ideal for OEMs, data centers, and equipment manufacturers requiring plug-and-play solutions.

- Factory-tested for performance, reliability, and compliance.

The Box Build Assembly Process at Actenn

At Actenn, we follow a streamlined, step-by-step process to deliver precision-engineered box build assemblies. Our approach ensures consistency, efficiency, and adherence to client requirements.

1. Design Consultation and Requirements Gathering

- Collaborate with clients to understand project goals, specifications, and application needs.

- Develop 3D models, schematics, and assembly layouts for approval.

2. Material Procurement

- Source high-quality components, including connectors, enclosures, PCBs, and wiring harnesses.

- Ensure all materials comply with international standards for safety and quality.

3. Component Integration and Assembly

- Assemble mechanical, electrical, and electronic components into the enclosure.

- Precision wiring ensures efficient cable routing, labeling, and strain relief.

4. Functional and Performance Testing

- Conduct rigorous testing, including:

- Electrical Testing: Verifies continuity, insulation, and load handling.

- Functional Testing: Ensures the system operates as intended under real-world conditions.

- Environmental Testing: Assesses performance under temperature, humidity, and vibration extremes.

5. Quality Control and Compliance

- Final inspections ensure adherence to ISO 9001, RoHS, and IPC standards.

- Provide detailed documentation, including test reports and compliance certificates.

6. Packaging and Delivery

- Secure packaging to protect assemblies during transit.

- On-time delivery of plug-and-play systems ready for immediate deployment.

Applications of Box Build Assembly Solutions

Actenn’s box build assemblies are designed for a wide range of industries, providing versatile and reliable solutions for critical applications. Key sectors include:

1. Industrial Automation

- Control panels and enclosures for managing robotics, production lines, and automated systems.

- Supports precision power distribution and real-time monitoring.

2. Data Centers

- Pre-assembled solutions for servers, network switches, and storage systems.

- Includes cable integration to optimize data flow and energy management.

3. Renewable Energy Systems

- Weatherproof assemblies for solar inverters, wind turbines, and energy storage units.

- Ensures durability and performance in outdoor conditions.

4. Medical Equipment

- Compact box builds for imaging systems, diagnostic machines, and monitoring devices.

- Precision wiring and integration for healthcare-grade reliability.

5. Telecommunications

- Enclosures for communication devices, networking equipment, and signal amplifiers.

- Designed to minimize electromagnetic interference and improve connectivity.

6. Aerospace and Defense

- Ruggedized assemblies for mission-critical systems, including unmanned vehicles and avionics.

- Built to perform under extreme conditions and vibration resistance.

Why Choose Actenn for Box Build Assembly Processing in Singapore?

Actenn has built a strong reputation as one of the leading box build assembly processing companies in Singapore by delivering reliable, tailored solutions. Here’s why businesses choose Actenn:

1. Industry Expertise

With decades of experience, we understand the complexities of diverse industries and deliver customized solutions that meet operational challenges.

2. Fully Customized Designs

Tailored assemblies that align with specific client needs, ensuring seamless integration and optimal performance.

3. Advanced Manufacturing Facilities

State-of-the-art equipment and automated processes ensure consistent product quality and precision engineering.

4. Comprehensive Testing

Every box build assembly undergoes functional, electrical, and environmental testing to guarantee reliability and durability.

5. Compliance with Global Standards

Adherence to ISO 9001, RoHS, and IPC standards ensures safety, quality, and environmental responsibility.

6. End-to-End Project Support

From consultation and design to delivery and after-sales support, Actenn provides complete project management.

Client Testimonials

“Actenn’s box build assembly solutions have streamlined our operations. Their attention to quality and precision is unmatched.”

– Emily Tan, Operations Manager, TechWorks Pte Ltd

“We trust Actenn for their reliable and scalable box build assemblies. Their expertise has been invaluable for our projects.”

– Ravi Menon, Project Lead, GreenEnergy Systems

Call to Action

Looking for trusted box build assembly processing companies in Singapore? Actenn delivers customized, high-performance solutions to meet your operational needs.

Contact us today to learn how our precision-engineered box build assemblies can optimize your systems.

Visit our website: Actenn.com or reach out for a personalized consultation.

Following Products Are Available Under Box Build Assembly Processing Companies in Singapore:

Actenn Products And Services:

Industrial & Automotive Cables

Industrial & Automotive Cables

Automotive cables near me in Singapore

Automotive fiber optic cable in Singapore

Automotive power cable in Singapore

Automotive wire harness plugs in Singapore

Automotive wire harnesses manufacturers in Singapore

Braided automotive cable in Singapore

Car cable manufacturers in Singapore

Automotive wire and cable manufacturers in Singapore

Automotive wire connectors suppliers in Singapore

Automotive electrical cable suppliers in Singapore

Automotive electrical wiring supplies in Singapore

Automotive wiring accessories suppliers in Singapore

Automotive cables manufacturer in Singapore

Automotive wire and cable suppliers in Singapore

Top ten automotive wire manufacturers in Singapore

Best automotive wiring harness manufacturers in Singapore

High temperature automotive wire producer in Singapore

Automotive wiring harness components manufacturer in Singapore

Automotive high voltage cable manufacturer in Singapore

Automotive electrical wire for sale in Singapore

Custom automotive wire harness manufacturers in Singapore

Industrial & automotive cables in Singapore

Automotive electrical wire in Singapore

Custom automotive wire harness manufacturers in Singapore

Automotive wire harness manufacturers in Singapore

Custom wire harness automotive in Singapore

Automotive cable manufacturer in Singapore

Industrial automation cables in Singapore

Industrial cable assemblies in Singapore

Industrial electrical cable in Singapore

Industrial usb cable in Singapore

Auto power wire harness manufacturers in Singapore

Box Build Control Panel

Box Build Control Panel

Box build assembly in Singapore

Electrical panel assembly in Singapore

Electrical box assembly manufacturer in Singapore

Best box assembly service provider in Singapore

Custom box assembly manufacturing in Singapore

Box build assembly process in Singapore

Control boxes manufacturer in Singapore

Box build manufacturing in Singapore

Control box assembly producer in Singapore

Electrical control box assembly manufacturer in Singapore

Control panel box design in Singapore

Box build assembly processing companies in Singapore

Electrical control box assembly in Singapore

Cable assembly for artificial intelligence

Cable assembly for data center

Cable assembly for medical equipment

Cable assembly for electric vehicle

Cable assembly for unmanned vehicle

Defense Optics and Fiber Technology

Defense Optics and Fiber Technology

Defense optics and fiber technology in Singapore

Fiber optic manufacturers in Singapore

Best fiber optic cable manufacturers in Singapore

Best optical fiber cable manufacturers in Singapore

Fiber optic cable suppliers in Singapore

Best fiber optic cable installation companies in Singapore

Best quality fiber optic cables for sale in Singapore

Best optical fiber system producer in Singapore

Defense optical systems in Singapore

Printed Circuit Board Assembly

Printed circuit board assembly

Pcb printed circuit board assembly in Singapore

Printed circuit board and assembly in Singapore

Printed circuit board pcb assembly in Singapore

Printed circuit board assembly manufacturer in Singapore

Pcba manufacturing companies in Singapore

Control panel assembly in Singapore

Pcb component assembly process in Singapore

Pcba main board supplier in Singapore

Pcba circuit board supplier in Singapore

Printed circuit board assembly pcba in Singapore

Pcba printed circuit board assembly in Singapore

Printed circuit board assembly supplier in Singapore

Printed circuit board assembly companies in Singapore

Printed circuit board manufacturers in Singapore

Cheap pcb assembly suppliers in Singapore

Pcb assembly services in Singapore

Pcb fabrication and assembly in Singapore

Pcb assembly contract manufacturer in Singapore

Printed circuit board assembly services in Singapore

Pcb design and development in Singapore

Printed circuit board design companies in Singapore

Pcb manufacturing companies near me

Circuit board manufacturing companies near me

Custom printed circuit board manufacturers in Singapore

Printed circuit board assembly manufacturers in Singapore

Printed circuit boards design fabrication and assembly in Singapore

Military Defense Cables & Harnesses

Military defense cables & harnesses

Military cable assemblies in Singapore

Military cable harness in Singapore

Cable harness manufacturer in Singapore

Cable harness suppliers in Singapore

Wire harness supplier in Singapore

Military cable assembly manufacturers in Singapore

Electrical harness manufacturers in Singapore

Cable harness manufacturers in Singapore

Military wiring harnesses in Singapore

Custom cable assembly manufacturers in Singapore

Wire harness manufacturer in Singapore

Cable harness assembly suppliers in Singapore

Wire harness manufacturers in Singapore

Aerospace cable manufacturers in Singapore

Aerospace wire harness manufacturers in Singapore

Wire and harness manufacturers in Singapore

Aerospace cable assembly manufacturers in Singapore

Top wiring harness manufacturers in Singapore

Wiring harness suppliers in Singapore

Aerospace cable assemblies in Singapore

Cable harness supplier in Singapore

Wiring harness companies in Singapore

Wire harness cable assembly manufacturing in Singapore

Electric & Power Cables

Electric & power cables

Electrical power line installers and repairers in Singapore

Electrical cable supplier in Singapore

Industrial cable manufacturers in Singapore

Best wire and cable distributors in Singapore

Industrial cable management service in Singapore

Industrial electric wire and cable supplier in Singapore

Industrial electrical cable suppliers in Singapore

Multi conductor power cable manufacturers in Singapore

Electrical wire manufacturers in Singapore

Power electric cable in Singapore

Electrical power cable assembly in Singapore

Electrical cable manufacturers in Singapore

Best wire and cable manufacturers in Singapore

Power cable manufacturer in Singapore

Best industrial cables suppliers in Singapore

Industrial power cable suppliers in Singapore

Industrial cable connector supplier in Singapore

Industrial cable protector supplier in Singapore

Best industrial electric wire and cable company in Singapore

Industrial wire and cable manufacturers in Singapore

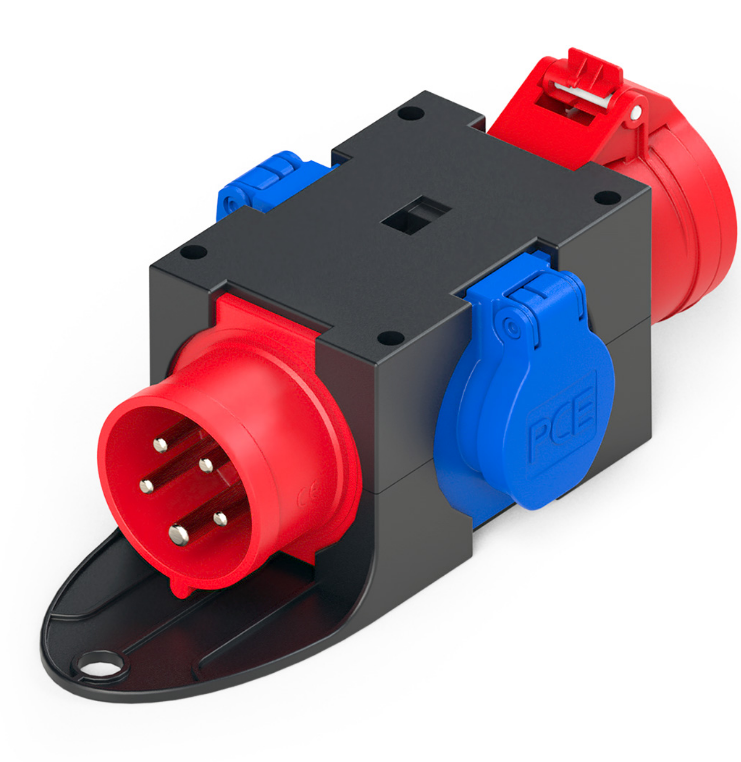

PCE Industrial CEE & Power Connectors

Pce industrial cee & power connectors

Cee form plugs and sockets in Singapore

Cee form connector in Singapore

Cee sockets & plugs in Singapore

Cee industrial socket in Singapore

Cee plugs and sockets in Singapore

Pce electric distributors in Singapore

Pce industrial plug and socket in Singapore

Pce industrial socket in Singapore

Pce industrial socket suppliers in Singapore

Pce industrial sockets in Singapore

Pce plug and socket in Singapore

Cee industrial plug and socket in Singapore

Industrial plugs and connectors in Singapore

Pce industrial plugs sockets Singapore

Pce plug and socket Singapore