Box Build Assembly in Singapore: Comprehensive Solutions by Actenn

In today’s fast-paced manufacturing landscape, efficient and reliable Box Build Assembly in Singapore plays a pivotal role in delivering complete, ready-to-install solutions for industries. Box build assemblies, also known as system integrations, are essential for integrating electronic, electrical, and mechanical components into a single enclosure or system. Actenn, a trusted provider in Singapore, delivers high-quality box build assembly services tailored to meet the unique demands of businesses across various sectors.

This section explores Actenn’s expertise in box build assemblies, their features, applications, and why Actenn is the ideal partner for advanced system integration solutions.

Introduction to Box Build Assembly in Singapore

A box build assembly refers to the process of integrating subassemblies, components, and enclosures into a functional product. These assemblies often involve cable installations, printed circuit board (PCB) integration, wiring, testing, and quality control. At Actenn, we provide reliable and customized Box Build Assembly in Singapore to deliver turnkey solutions for our clients, ensuring every product is ready for deployment.

Our skilled team specializes in system integration and focuses on precision, quality, and on-time delivery. Actenn serves a diverse range of industries, including electronics, automation, medical, energy, and defense sectors, providing comprehensive assembly solutions that exceed expectations.

Why Box Build Assembly is Essential

Box build assembly is a critical part of the manufacturing and production process for systems that require seamless integration. Its importance lies in its ability to:

- Reduce Production Time: Provides a ready-to-use solution, reducing assembly efforts at the client’s end.

- Enhance System Efficiency: Ensures the smooth functioning of all integrated components.

- Ensure Quality and Precision: Involves rigorous testing to ensure optimal performance.

- Provide Scalability: Supports quick integration and deployment in growing industries.

- Simplify Supply Chain: A single vendor for assembly and integration simplifies logistics and project management.

At Actenn, our box build assembly services offer these benefits, allowing businesses to focus on their core operations while we handle the integration process.

Key Features of Actenn’s Box Build Assembly Services

- Turnkey Integration: Complete end-to-end assembly of components, subassemblies, and systems.

- Custom Solutions: Tailored box build services to meet specific industry requirements.

- High-Quality Components: Use of reliable and certified parts to ensure durability and performance.

- Rigorous Testing: Comprehensive testing, including functional, electrical, and environmental checks.

- On-Time Delivery: Efficient project management to meet delivery deadlines and maintain consistency.

- Global Standards Compliance: Adheres to ISO 9001, IPC, and RoHS certifications for quality assurance.

Actenn’s Core Box Build Assembly Offerings

Actenn provides a comprehensive range of box build assembly solutions to support industries in Singapore and beyond. Here are our key offerings:

1. Complete System Integration

- Full assembly of components, PCBs, cables, and enclosures.

- Seamless integration of mechanical and electrical parts.

- Turnkey solutions for plug-and-play systems ready for immediate use.

2. PCB and Cable Assembly Integration

- High-quality printed circuit board assembly and wiring solutions.

- Custom cable harnesses integrated into enclosures or systems.

- Ensures smooth electrical connectivity and system performance.

3. Custom Enclosure Assembly

- Design and assembly of enclosures to fit specific dimensions and applications.

- Includes metal, plastic, and hybrid enclosure options.

- Aesthetically appealing and functional designs for diverse applications.

4. Testing and Quality Control

- Functional testing, electrical verification, and environmental testing.

- Ensures systems meet client specifications and global standards.

- Reduces risks of malfunction and enhances reliability.

5. Packaging and Logistics Support

- Secure packaging to prevent damage during transport.

- Labeling, kitting, and documentation support for turnkey solutions.

- Efficient logistics to deliver ready-to-install systems to clients.

Applications of Box Build Assembly

Actenn’s box build assembly services cater to various industries, providing solutions for a wide range of applications. Here are the key industries that benefit from our expertise:

1. Industrial Automation

- Integrated control systems for machinery and automation equipment.

- Custom enclosures housing sensors, controllers, and power supplies.

- Enhances reliability and performance in automated production systems.

2. Electronics and IoT

- Complete systems for smart devices and IoT solutions.

- Integrated PCBs, wiring, and sensors for connected applications.

- Compact and durable assemblies for smart homes and industrial IoT.

3. Medical Equipment

- Custom enclosures for diagnostic, imaging, and monitoring devices.

- Cable assemblies integrated with sensors and power management systems.

- Precision testing to ensure compliance with medical standards.

4. Energy and Renewable Solutions

- Power distribution systems for renewable energy installations.

- Integrated solar inverters, battery management systems, and control units.

- Weatherproof enclosures for outdoor energy applications.

5. Defense and Aerospace

- Ruggedized enclosures and assemblies for military-grade equipment.

- High-performance systems for unmanned vehicles, radar, and surveillance systems.

- Compliance with MIL-STD and aerospace standards.

Why Choose Actenn for Box Build Assembly in Singapore?

Actenn’s reputation for delivering exceptional box build assembly services is built on innovation, reliability, and precision. Here’s why businesses trust us for their system integration needs:

1. Industry Expertise

With years of experience serving multiple industries, Actenn has a deep understanding of box build assembly processes, ensuring reliable and efficient solutions.

2. Customization

Our tailored box build solutions address specific client requirements, from component selection to system integration and final testing.

3. Advanced Manufacturing

We leverage state-of-the-art facilities and advanced production techniques to deliver consistent quality.

4. Rigorous Quality Assurance

Every assembly undergoes thorough testing and inspection to ensure performance, durability, and compliance with international standards.

5. End-to-End Support

From design and prototyping to assembly, testing, and logistics, we provide seamless support at every stage of the project.

How Actenn Ensures Quality in Box Build Assembly

Quality is the cornerstone of Actenn’s operations. Our robust quality assurance process includes:

- Material Selection: Use of certified and high-quality components.

- Precision Assembly: Advanced tools and equipment ensure accuracy and consistency.

- Comprehensive Testing: Functional, electrical, and environmental testing to validate performance.

- Global Standards Compliance: Adherence to ISO 9001, IPC-A-610, and RoHS certifications.

Client Testimonials

“Actenn’s box build assembly services have streamlined our production process. Their precision and reliability are second to none.”

- Emily Tan, Operations Manager, TechInnovate Solutions

“We trust Actenn for all our box build needs. Their team’s expertise and attention to detail have consistently exceeded our expectations.”

- Ravi Menon, Head of Production, GreenTech Systems

Sustainability in Box Build Assembly

Actenn is committed to sustainability in manufacturing processes. We prioritize energy efficiency, waste reduction, and the use of eco-friendly materials, ensuring our box build assemblies are reliable while minimizing environmental impact.

Call to Action

Looking for reliable Box Build Assembly in Singapore? Actenn provides comprehensive and high-quality solutions tailored to your industry’s unique requirements.

Contact us today to discuss your project and discover how Actenn can deliver precision-engineered box build assemblies for your business needs.

Visit our website: Actenn.com or reach out to us for a personalized consultation.

Following Products Are Available Under Box Build Assembly in Singapore:

Actenn Products And Services:

Industrial & Automotive Cables

Industrial & Automotive Cables

Automotive cables near me in Singapore

Automotive fiber optic cable in Singapore

Automotive power cable in Singapore

Automotive wire harness plugs in Singapore

Automotive wire harnesses manufacturers in Singapore

Braided automotive cable in Singapore

Car cable manufacturers in Singapore

Automotive wire and cable manufacturers in Singapore

Automotive wire connectors suppliers in Singapore

Automotive electrical cable suppliers in Singapore

Automotive electrical wiring supplies in Singapore

Automotive wiring accessories suppliers in Singapore

Automotive cables manufacturer in Singapore

Automotive wire and cable suppliers in Singapore

Top ten automotive wire manufacturers in Singapore

Best automotive wiring harness manufacturers in Singapore

High temperature automotive wire producer in Singapore

Automotive wiring harness components manufacturer in Singapore

Automotive high voltage cable manufacturer in Singapore

Automotive electrical wire for sale in Singapore

Custom automotive wire harness manufacturers in Singapore

Industrial & automotive cables in Singapore

Automotive electrical wire in Singapore

Custom automotive wire harness manufacturers in Singapore

Automotive wire harness manufacturers in Singapore

Custom wire harness automotive in Singapore

Automotive cable manufacturer in Singapore

Industrial automation cables in Singapore

Industrial cable assemblies in Singapore

Industrial electrical cable in Singapore

Industrial usb cable in Singapore

Auto power wire harness manufacturers in Singapore

Box Build Control Panel

Box Build Control Panel

Box build assembly in Singapore

Electrical panel assembly in Singapore

Electrical box assembly manufacturer in Singapore

Best box assembly service provider in Singapore

Custom box assembly manufacturing in Singapore

Box build assembly process in Singapore

Control boxes manufacturer in Singapore

Box build manufacturing in Singapore

Control box assembly producer in Singapore

Electrical control box assembly manufacturer in Singapore

Control panel box design in Singapore

Box build assembly processing companies in Singapore

Electrical control box assembly in Singapore

Cable assembly for artificial intelligence

Cable assembly for data center

Cable assembly for medical equipment

Cable assembly for electric vehicle

Cable assembly for unmanned vehicle

Defense Optics and Fiber Technology

Defense Optics and Fiber Technology

Defense optics and fiber technology in Singapore

Fiber optic manufacturers in Singapore

Best fiber optic cable manufacturers in Singapore

Best optical fiber cable manufacturers in Singapore

Fiber optic cable suppliers in Singapore

Best fiber optic cable installation companies in Singapore

Best quality fiber optic cables for sale in Singapore

Best optical fiber system producer in Singapore

Defense optical systems in Singapore

Printed Circuit Board Assembly

Printed circuit board assembly

Pcb printed circuit board assembly in Singapore

Printed circuit board and assembly in Singapore

Printed circuit board pcb assembly in Singapore

Printed circuit board assembly manufacturer in Singapore

Pcba manufacturing companies in Singapore

Control panel assembly in Singapore

Pcb component assembly process in Singapore

Pcba main board supplier in Singapore

Pcba circuit board supplier in Singapore

Printed circuit board assembly pcba in Singapore

Pcba printed circuit board assembly in Singapore

Printed circuit board assembly supplier in Singapore

Printed circuit board assembly companies in Singapore

Printed circuit board manufacturers in Singapore

Cheap pcb assembly suppliers in Singapore

Pcb assembly services in Singapore

Pcb fabrication and assembly in Singapore

Pcb assembly contract manufacturer in Singapore

Printed circuit board assembly services in Singapore

Pcb design and development in Singapore

Printed circuit board design companies in Singapore

Pcb manufacturing companies near me

Circuit board manufacturing companies near me

Custom printed circuit board manufacturers in Singapore

Printed circuit board assembly manufacturers in Singapore

Printed circuit boards design fabrication and assembly in Singapore

Military Defense Cables & Harnesses

Military defense cables & harnesses

Military cable assemblies in Singapore

Military cable harness in Singapore

Cable harness manufacturer in Singapore

Cable harness suppliers in Singapore

Wire harness supplier in Singapore

Military cable assembly manufacturers in Singapore

Electrical harness manufacturers in Singapore

Cable harness manufacturers in Singapore

Military wiring harnesses in Singapore

Custom cable assembly manufacturers in Singapore

Wire harness manufacturer in Singapore

Cable harness assembly suppliers in Singapore

Wire harness manufacturers in Singapore

Aerospace cable manufacturers in Singapore

Aerospace wire harness manufacturers in Singapore

Wire and harness manufacturers in Singapore

Aerospace cable assembly manufacturers in Singapore

Top wiring harness manufacturers in Singapore

Wiring harness suppliers in Singapore

Aerospace cable assemblies in Singapore

Cable harness supplier in Singapore

Wiring harness companies in Singapore

Wire harness cable assembly manufacturing in Singapore

Electric & Power Cables

Electric & power cables

Electrical power line installers and repairers in Singapore

Electrical cable supplier in Singapore

Industrial cable manufacturers in Singapore

Best wire and cable distributors in Singapore

Industrial cable management service in Singapore

Industrial electric wire and cable supplier in Singapore

Industrial electrical cable suppliers in Singapore

Multi conductor power cable manufacturers in Singapore

Electrical wire manufacturers in Singapore

Power electric cable in Singapore

Electrical power cable assembly in Singapore

Electrical cable manufacturers in Singapore

Best wire and cable manufacturers in Singapore

Power cable manufacturer in Singapore

Best industrial cables suppliers in Singapore

Industrial power cable suppliers in Singapore

Industrial cable connector supplier in Singapore

Industrial cable protector supplier in Singapore

Best industrial electric wire and cable company in Singapore

Industrial wire and cable manufacturers in Singapore

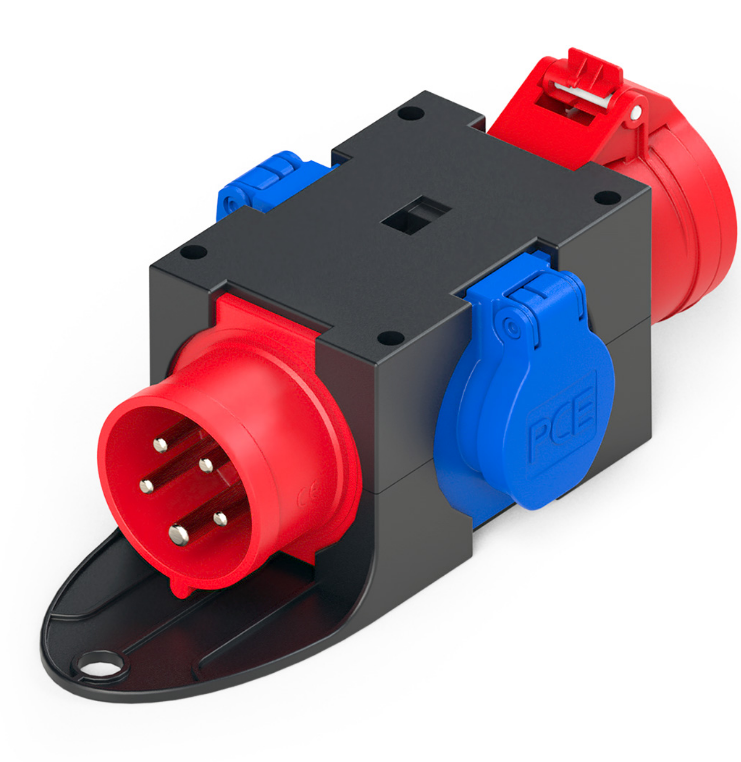

PCE Industrial CEE & Power Connectors

Pce industrial cee & power connectors

Cee form plugs and sockets in Singapore

Cee form connector in Singapore

Cee sockets & plugs in Singapore

Cee industrial socket in Singapore

Cee plugs and sockets in Singapore

Pce electric distributors in Singapore

Pce industrial plug and socket in Singapore

Pce industrial socket in Singapore

Pce industrial socket suppliers in Singapore

Pce industrial sockets in Singapore

Pce plug and socket in Singapore

Cee industrial plug and socket in Singapore

Industrial plugs and connectors in Singapore

Pce industrial plugs sockets Singapore

Pce plug and socket Singapore